Mercaptan Sensor Case Study

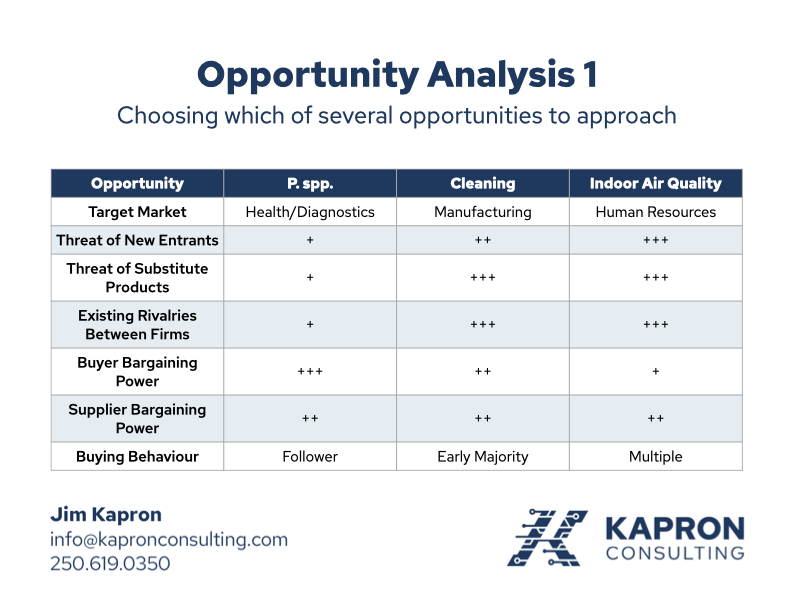

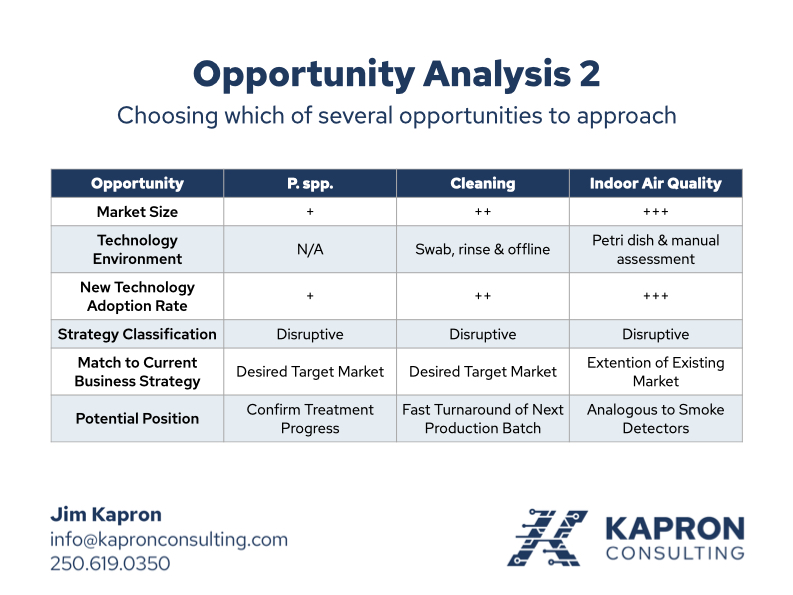

An established research company with a single technology needed to expand and diversify their offerings. Kapron Consulting was brought in to explore opportunities and help their recently patented product find markets.

Value Propositions

Like many academics, the client believed customers would flock to them without effort. I provided the value proposition for several application areas including the following.

Format 1: Summary

A specific lung disease (confidential)

For this application, therapeutic lung massage and pulmonary anti-bacterial treatments prove effective. Early assessment of the treatment's effectiveness improves outcomes, reduces the cost of treatment, and increases the efficiency of the treatment centre.

This product monitors the 22 volatile organic compounds produced by Pseudomonas spp. to demonstrate that small initial changes in concentration occur during treatment.

Once the small initial changes are observed, the progress of therapy can be monitored for a suitable endpoint. As a result, the treatment is stopped at the optimal time. The cost of treatment is optimized to the specific procedure. The treatment centre procedures are optimized for individual cases increasing efficiency.

Format 2: Detailed

Cleaning Validation

Background: In product manufacturing, sulfur compounds are an indication of product degradation or non-sterile conditions. Complete removal of a previous batch ensures conditions for the next production batch are optimized.

Key Pain Points: The current process is time and labour intensive. After batch cleanup, a technician swabs surfaces, or rinses the instrumentation and collects the rinse water. Swabs and liquid samples are then taken from production to the research laboratory in a different part of the factory. Measurement can be delayed by transport and by the sample queue, resulting in lost time at the production line.

Competitive Landscape: Numerous industries and technologies compete for this market space. Vendors usually stress either the instrument or the sampling method. A new product could stand out if it:

- Continuously monitors at the production line

- Monitors all the sulfur compounds of interest

- Has a zero false negative rate

- Has a low false positive rate

- Uses simple software

- Automatically calibrates with minimal user effort.

Value Proposition: The analyzer monitors surface cleanliness by sniffing for volatile sulfur compounds. The technician calibrates before daily use and brings the hand held sniffer to the production line. During post-batch standard operating procedure cleaning, the sulfur compound concentration decreases. At the end of the procedure, one final wave of the sniffer ensures that sulfur compounds are removed and the next step can take place.

Format 2: Detailed

Indoor Air Quality

Background: Molds and mold degradation products contain allergens and irritants turning work spaces into productivity sinks. Hidden leaks and moist conditions between walls are breeding grounds for toxic molds. Government agencies, the construction industry, and consumer organizations are increasingly recognizing the effect of mold in homes and offices. Increasing extreme weather conditions imply that people will spend more time indoors.

Key Pain Points: Mold has health effects before it can be smelled. Lost wages due to sicknesses (asthma), lethargy, and smell. Risk of lawsuit due to unsafe working conditions.

Competitive Landscape: Competitive industries include contract laboratories and cell-based assay suppliers. Competitive technologies include cell-based assays (microbiological tests). The current method for sample collection is to set a Petri dish in the office space to trap mold spores. After 24 hours, the dish is sent to a contract lab for analysis. The process requires the spores to grow which may take up to two weeks in culture.

Value Proposition: Governments, the construction industry, and consumers are concerned about the presence of mold in homes and work spaces. The product line monitors volatile mold degradation products and warns of the presence of mold over established limits. The instrument can be placed between walls or in humid environments to monitor changes in mold levels. The key benefit is that it senses mold before it can become a major problem. Workers are reassured that the work space is reliably clean. The product forms part of the company's occupational health and safety risk mitigation program.

Product Notes

Positioning Statement

For natural gas industry associations, the product is the most reliable and cost-effective method to monitor sweet gas.

Key Benefits

- Reliability: substitute manual operation with continuous monitoring.

- Reduced operating costs: substitute operator training with instrumentation.

Reliability comes from continuous mercaptan monitoring so you are never out of touch with system conditions. All measurement points are connected to a central control site, permitting instant response to situations.

Outstanding accuracy in a hand held with the same as bench instruments in major laboratories. World-class analysis is now on your site, with easy-to-use and very low maintenance instruments.

Unlike other mercaptan measuring instruments, the product uses no radioactive parts. This key development gives added safety to the system via patented non-radioactive technology.

The product is checked at the start of each shift and only needs to be calibrated annually with a simple, on-site, five-minute process. Compare that with the monthly training required for operators of the current system. The return on investment advantages are clear. The product comes with cross-validation guidance for easy adaptation of eastablished SOPs.

False positives and false negatives are less likely because of the specificity of the combined technologies. Individual mercaptans as well as total mercaptan levels are identified.

The product allows you to participate in the growth of this technology. Future capability includes the detection of BTEX. The system you buy can be easily upgraded as new measurements become available. The hand held software powering the system is user-friendly.

Features

- No radioactive parts

- Single or continuous operation

- Exportable data files

- Simple to use software

Sample Type

- Air or natural gas

Application Specifications

- Measurement of mercaptans in natural gas lines

- Testing mercaptan levels at check points and gate stations

- Total mercaptans

- Custom applications

Technical Specifications

|

Sample type |

Mercaptans in air or natural gas |

|

Concentration range |

10ppb - 10ppm |

|

Operating temperature |

5 to 30°C |

|

Sample gas humidity |

0 – 95% noncondensing |

|

Sample gas pressure |

Ambient pressure |

|

Sample gas temperature |

5 to 50°C |

|

T90 measurement time |

3 seconds |

|

Accuracy |

<0.1% full scale |

|

Resolution |

± 0.1% |

|

Internal sensors |

Temperature and pressure |

|

Start up time |

5 seconds |

|

Storage conditions |

-20 to 50C |

|

Weight |

600 grams |

|

Supply voltage |

Rechargeable 3VDC battery |

|

Dimensions |

9 cm (w) x 15 cm (h) x 4 cm (d) |

|

Alarm notification |

Audible <90dB and visual |

|

Part number |

SCMS-110 |